On June 25, the RM workshop was filled with joy and excitement as the first D25 engine of Shanghai Diesel Engine Co., Ltd. (hereinafter referred to as the Company) officially rolled off the production line, marking a major breakthrough in the Company’s new product development and a solid step forward on the road to marketization.

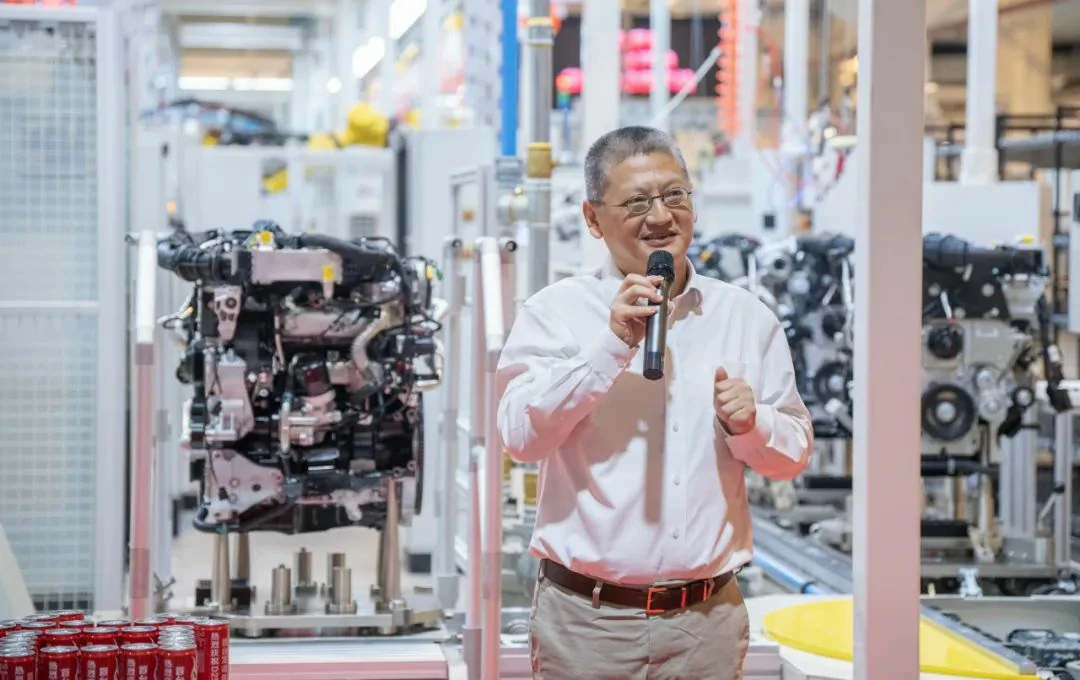

SAIC MAXUS leader Gong Weiguo, company deputy general managers Tan Sheng and Chen Yong, D25 project product chief designer Zhu Guohua, product directors Liu Fei and Zhou Zhiguang, manufacturing director Lu Hongfei, planning and logistics director Xu Mingyang, quality director Jin Tianzhu, manufacturing engineering director Chen Xin, as well as department leaders from procurement, logistics, projects, engineering, quality and production and manufacturing sectors of both companies witnessed this festive moment together.

The D25 project represents a new speed for the company’s independent engine development. From the start of the project pre-research in 2021, to the ignition of the first prototype in August 2022, to today’s trial production, the D25 has been evolving and growing at a pace that changes with each passing day.

SAIC Maxus leader Gong Weiguo visited the production line on site, listened to the situation report of the PPV stage, and asked the joint team to further work and accelerate the resolution and verification of problems. He pointed out at the offline ceremony that the project cycle of the D25 project is unprecedented in the history of our independent engine development. The project cycle is short and the proportion of new supporting suppliers is high. Whether it is the design end, the process end or the manufacturing end, it faces huge challenges. The joint team completed the PPV production of the project on time through efficient collaboration, which proved our ability and determination. We expect the D25 product to play an important role in enriching our product series and opening up new markets. Today’s offline ceremony represents the D25 project’s shift from development focus to production and manufacturing. After the engine is offline, it will be installed on the new generation of Maxus pickup trucks and will be launched in the near future.

Tan Sheng, the company’s deputy general manager, spoke at the off-line ceremony. He said that the D25 project was approved by the group’s PG8 in March 2022 and the group’s PG6 in August 2023, leaving a very short period for production line construction. However, the project team and the supplier team overcame all difficulties and achieved the node ahead of schedule. This speed is another new record in the history of New Power, and it embodies the sweat and wisdom of the project’s employees and all the support teams. The VM workshop has always been the benchmark for New Power’s lean production. D20 is the company’s lean indicator and intelligent manufacturing double-excellent workshop. Now the elites of these two teams have been combined to form the D25 project launch team, which is currently the strongest project management team of New Power. The company has full confidence in completing this project. D25 is stronger than D20 in terms of power and fuel consumption, and we look forward to this product bringing greater surprises.

The company’s VM engine has produced 334,000 units in 13 years, and the D20 project, which was successfully cooperated with SAIC Maxus, achieved the same sales volume in just 5 years. In the past resume of New Power Company, VM and D20 engines represent the acceleration of New Power’s rapid development. Today, New Power Company and Maxus have witnessed the first product of D25 pre-trial production roll off the production line, with unlimited prospects and a promising future.