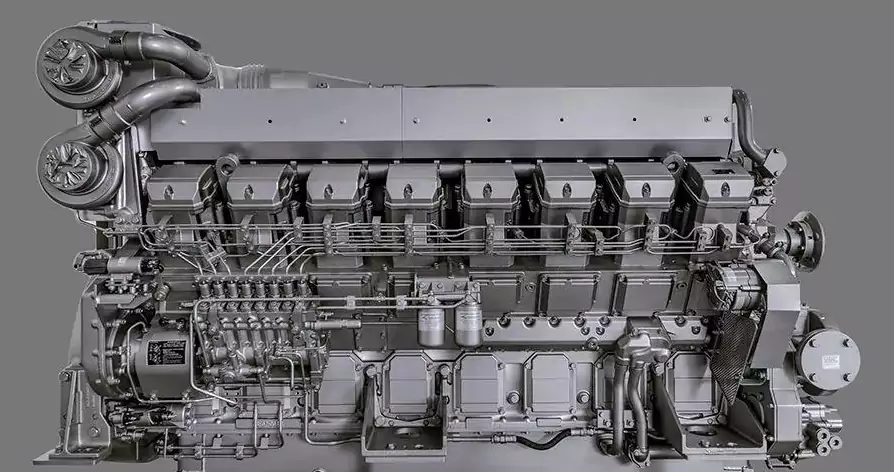

SDEC 4HTAA4.3-G34 G-Drive Engine

SDEC 4HTAA4.3-G34 Generator Drive Engine uses a 4 Cylinder design, simple structure, the overall size is smaller than the same power diesel engine.

With supercharging and intercooling technology, the 4HTAA4.3-G34 generator drives the engine (1500 RPM) with a displacement of 4.3 L.

The Engine has a maximum power output of 105 kW, enough provide high performance, which is important for applications that require quick acceleration or long distance runs.

We provide all customers with full life cycle services from design to power system supply, from installation to commissioning, from after-sales service training to spare parts supply, from troubleshooting to maintenance technical support.

Advantages of 4HTAA4.3-G34 G-Drive Engine

SDEC 4HTAA4.3-G34 Generator Drive Engine adopts microcomputer control system, good overall technical design, production and assembly are more in line with the standard technical requirements, and discard the technical design defects of the assembly unit.

The engine uses a new combustor to increase the fuel injection pressure, improve the combustion process, and achieve environmental protection indicators: engine emissions meet non-road country III emission standards.

The 4HTAA4.3-G34 generator Drive Engine optimizes the design of the lubrication and cooling system, reduces the number of external pipelines and parts, and uses the whole brushless alternator to greatly improve the three leakage and greatly enhance the reliability.

The engine has the advantages of large power, low fuel consumption, easy start, low emission, low vibration noise, easy maintenance and use.

Technical Specifications

| Model: | 4HTAA4.3-G34 |

| Prime Power: | 105 kW |

| Engine Type: | In-line, 4 Strokes, 4 Valves, Water-Cooled |

| Rated Power / Speed: | 636 kW @ 1500 RPM |

| Combustion Type: | Direct Injection |

| Firing Order: | 1-3-4-2 |

| Number of Cylinders: | 4 |

| Injection Timing: | 10 °BTDC |

| Bore * Stroke: | 105 mm * 124 mm |

| Dry Weight: | 400 kg |

| Displacement: | 4.3 L |

| Dimension (L * W * H): | 1037 mm * 728 mm * 1024 mm |

| Lead Time: | 15-30 Working Days |

| Payment Terms: | T/T ,L/C |

EngineModel | Prime Power | Displacement | Aspiration |

| 4HT4.3-G21 | 62 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HT4.3-G22 | 67 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HT4.3-G23 | 86 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G21 | 105 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G22 | 120 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G23 | 120 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G31 | 62 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G32 | 67 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G33 | 86 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G34 | 105 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G35 | 120 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 4HTAA4.3-G36 | 125 kW @ 1800 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| 6HTAA6.5-G21 | 136 kW @ 1800 RPM | 6.5 L | Turbocharged & Water-Air Intercooled |

| 6HTAA6.5-G22 | 150 kW @ 1800 RPM | 6.5 L | Turbocharged & Water-Air Intercooled |

| 6HTAA6.5-G23 | 180 kW @ 1800 RPM | 6.5 L | Turbocharged & Water-Air Intercooled |

| 6HTAA6.5-G31 | 136 kW @ 1800 RPM | 6.5 L | Turbocharged & Water-Air Intercooled |

| 6HTAA6.5-G32 | 150 kW @ 1800 RPM | 6.5 L | Turbocharged & Water-Air Intercooled |

| 6HTAA6.5-G33 | 180 kW @ 1800 RPM | 6.5 L | Turbocharged & Water-Air Intercooled |

| 6HTAA6.5-G34 | 205 kW @ 1800 RPM | 6.5 L | Turbocharged & Water-Air Intercooled |

| 6HTAA6.5-G35 | 170 kW @ 1800 RPM | 6.5 L | Turbocharged & Water-Air Intercooled |

| SC4H95D2 | 62 kW @ 1500 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| SC4H115D2 | 78 kW @ 1500 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| SC4H140D2 | 95 kW @ 1500 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| SC4H160D2 | 105 kW @ 1500 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| SC4H180D2 | 120 kW @ 1500 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| SC7H180D2 | 120 kW @ 1500 RPM | 4.3 L | Turbocharged & Water-Air Intercooled |

| SC7H205D2 | 138 kW @ 1500 RPM | 6.44 L | Turbocharged & Water-Air Intercooled |

| SC7H220D2 | 150 kW @ 1500 RPM | 6.44 L | Turbocharged & Water-Air Intercooled |

| SC7H230D2 | 154 kW @ 1500 RPM | 6.44 L | Turbocharged & Water-Air Intercooled |

| SC7H250D2 | 168 kW @ 1500 RPM | 6.44 L | Turbocharged & Water-Air Intercooled |

| ——END—— | |||

General Infomation of SDEC-Shanghai Diesel 4HTAA4.3-G34 Generator Drive Engine | |||

| Engine Model | 4HTAA4.3-G34 | Engine Type | In-line,4 Strokes,Water-Cooled |

| Combustion Type | Direct Injection | Dimensions (L * W * H) | 1037 mm * 728 mm * 1024 mm |

| Number of Cylinders | 4 | Bore*Stroke (mm) | 105 mm * 124 mm |

| Displacement | 4.3 L | Compression Ratio | 17.3 : 1 |

| Prime Power | 105 kW | Standby Power (kW) | 116 kW |

| Engine Speed | 1800 RPM | Dry Weight (Kg) | 400 kg |

| ——END—— | |||

Performance Data of SDEC-Shanghai Diesel 4HTAA4.3-G34 Generator Drive Engine | |||

| Cylinder Type | Dry Liner | Rotation | CCW Viewed from Flywheel |

| Fly Wheel Housing | SAE NO.3 | Fly Wheel | SAE NO.11.5(Tooth Uumber of Gear:127) |

| Mechanism Type | Overhead Valve | Number of Valve | Intake 2, Exhaust 2 Per Cylinder |

| Cold Intake Valve Clearance | 0.25 mm | Cold Exhaust Valve Clearance | 0.5 mm |

| Heat Rejection to Coolant | 10.6 kcal/sec | Air Flow | 9.8 m³/min |

| Exhaust Gas Flow | 23.3 m³/min | Exhaust Gas Temp. | 600 °C |

| Max. Permissible Restrictions | 3 kPa | Intake System | 6 kPa |

| Exhaust System (Max.) | 8 kPa | Injection Timing | Electronic Control |

| ——END—— | |||

System Technical Data of SDEC-Shanghai Diesel 4HTAA4.3-G34 Generator Drive Engine | ||

| Fuel System | Injection Pump | Electronic Control |

| Governor | Electronic Control | |

| Feed Pump | Electronic Control | |

| Injection Nozzle | Multi Hole Type | |

| Opening Pressure | 180 MPa | |

| Fuel Filter | Full Flow, Cartridge Type | |

| Used Fuel | Diesel Fuel Oil | |

| Lubrication System | Lub. Method | Fully Forced Pressure Feed Type |

| Oil Pump | Gear Type Driven by Camshaft | |

| Oil Filter | Full Flow,Cartridge Type | |

| Oil Pan Capacity | High level 13 liters | |

| Low level 11 liters | ||

| Angularity Limit | Front Down 25 ° | |

| Front Up 35 ° | ||

| Side to Side 35 ° | ||

| Lub. Oil | Refer to Operation Manual | |

| Cooling System | Water Capacity(Engine Only) | 6.8 liters |

| Lid Min. Pressure | 70 kPa | |

| Water Pump | Centrifugal Type Driven by Belt | |

| Thermostat | Wax–Pellet Type | |

| Cooling Fan | Blower Type, Plastic | |

| The Max. temp. of Coolant in Prime/ Standby Power | 104/100 ℃ | |

| Electrical System | Charging Generator | 28 V * 35 A |

| Voltage Regulator | Built-On Type IC Regulator | |

| Starting Motor | 24 V * 5 kW | |

| Battery Voltage | 24 V | |

| Battery Capacity | 120 AH | |

| ——END—— | ||

Coming Soon

Note: All Above Data are Just for Reference, All Data Might Change Without Notices or Updates, Please Contact Our Sales Team to Confirm All Details Via WhatsApp or Email.

What's the Standard Scopes of Supply?

With full ranges of emission standard from Euro 2 to Euro 7, SDEC producing 12 series generator engines, started from 3.9 liter engine, to 15 liter engine, covering the power range of 125HP to 650HP.

SDEC generator engine customize developing configurations for big vehicle OEMs in China, based on each of requirement, SDEC producing dozens of different configuration engines with same engine model number, which only SO-Shop Order will be different with each other, the SO number is the identify number of the engine configuration of each model.

Even with same engine model, different SO number engine can have very different configuration with each other, with different prices. Some of SO-Shop Order is not available for commercial market, such as restricted models (Usually for military specifications).

EMAC offering most common, cost effective models which also able to process the production in SDEC, which usually have following accessories as standard configuration.

Scopes of Supply of SDEC Generator Drive Engine | |||

| Air Intake System | 1. Air Intake Manifold | Exhuast System | 1. Exhuast Manifold |

| 2. Standard Air Filter | 2. Turbocharger | ||

| 3. Water-Air Intercooler | 3. Exhuast Elbow | ||

| Starting System | 1. Starter Motor | Charging System | 1. Charging Alternator |

| 2. Starter Rely | 2. N/A | ||

| Lubricating System | 1. Oil Pump | Cooling System | 1. Water Pump |

| 2. Oil Filter | 2. Engine Fan | ||

| 3. N/A | 3. Standard Radiator | ||

| Engine Shut-Down System | 1. Engine Fuel Shut-Off Solenoid | Power Output System | 1. Flywheel |

| 2. N/A | 2. Standard Flywheel Housing | ||

| Fuel System | 1. Fuel Transfer Pump | ||

| 2. High-Pressure Fuel Pump | |||

| 3. Fuel Filter | |||

| ------END------ | |||

What's the Available Optional Items?

SDEC only provides customize service for the large quantity orders or large OEMs, which means usually the order quantity are higher than 1000 units. For the small quantity engine project, EMAC provides customize services with our own resource and engineer team.

EMAC have rich experience on the customize developing, which provides abundant optional items based on the requirement of each project. The typical optional items are special Prestolite charging alternator, prestolite starter motor, Knorr Air compressor. Valeo air conditioning compressor, ECU output socket set, engine accelerate pedal etc.

Optional Accessories of SDEC Generator Drive Engine | |||

| Air Intake System | 1. Air Intake Pre-Heater | Exhuast System | 1. Muffler & Bellows |

| 2. Air Intake Shut-Off Valve | 2. Spark Arrestor Type Muffler & Bellows | ||

| 3. Heavy-Duty Air Filter | 3. DPF System | ||

| 4. Plateau Type Air Filter | 4. N/A | ||

| Fuel System | 1. Coarse Filter | Lubricating System | 1. Oil Pre-Heater |

| 2. Fuel Pre-Heater | 2. N/A | ||

| Starting System | 1. Manual Magnetic DC Contactor | Cooling System | 1. Silent Type Radiator |

| 2. Dual Ears Flywheel Housing | 2. Plateau Radiator | ||

| 3. Spring Starter Motor | 3. Salt-Spray Resistant Radiator | ||

| 4. Air Starter Motor | 4. Coolant Pre-Heater | ||

| 5. Hydraulic Starter Motor | 5. Jacket Water Heater | ||

| 6. Manual Magnetic DC Contactor | 6. N/A | ||

| ------END------ | |||

As part of EMAC, SinoGen focusing on generator set related business, from Generator drive engine power pack to complete generator set, from generator control panel to synchronizing cabinet, from super silent type generator set to mobile power trailer, SinoGen provides professional one-stop solution for everything customer needed for generator set.

For more information of our complete generator set products, you are welcome to visit SinoGen homepage: www.sino-gen.com

What's the Modifiable Items and Scopes?

As explained in the standard scopes of supply, SDEC not able to provide customize developing for small quantity projects or small OEMs, so EMAC helps SME OEMs to provide customize services, not only providing additional optional items, but also provides customize modification services to meet their requirements based on the exisiting engine SO number.

As flexible service ability is our core advantages, EMAC is very experienced and good at providing customize services, the common customize services are as below:

1: AIr Intake System: Change the air intake direction.

2: Air Exhuast System: We are able to change the turbocharger direction as the interaction on installation could be occured, also change change the air exhuast direction.

3: Lubricating System: Modify lubricating system is one of the most common requirement from customer, we can provide flat-type engine oil pan, to lower down total engine height, which usually required for special vehicles. For the standard engine oil pan, we also can change the direction of the engine oil pan.

4: Cooling System: There are lots of options for the engine cooling system, for the engine fan, we can provide customize for the material of engine fan (plastic fan or steel fan), wind direction of the engine fan (blower fan or suction fan ) and types of engine fan (mechanical fan or electric control fan).

5: Power Output System: Most of electronic controlled SDEC generator engines are comes with SAE#1 flywheel housing now, while lots of customers need SAE#2 flywheel because of the housing of transmissio is SAE#2, so we have to provide customzie services for those customer, which need to modify flywheel housing, flywheel and starter motor, we also have PTO integrated type flywheel housing available, which can output the whole power of the engine from the PTO on the flywheel housing, we can also provide modification of the mounting side of the starter motor.

6: Electric System: All of SDEC engines are comes with standard 24V electric system, while some customer need to modify the electric system into 12V, we can also modify the starter motor and alternator into appointed brand or appointed specifications.

EMAC is your reliable professional power system partner, feel free to contact our services team to get detailed information about our standard scopes of supply, optional items and modifiable parts for our SDEC generator engine, we are ready to explore the journey of our cooperation.

Modifiable components of SDEC Generator Drive Engine | |||

| Air Intake System | 1. Installation Position of Air Filter | Charging System | 1. 12V Charging Alternator for 12V Electric System |

| 2. Upgrade to Heavy-Duty Type Air Fitler | 2. Explosion-Proof Charging Alternator | ||

| Exhuast System | 1. Position of Turbocharger | Lubricating System | 1. Oil Pan Position |

| 2. Water-Cooled Exhuast Manifold | 2. Number of Dipstick | ||

| 3. Water-Cooled Turbocharger | 3. Position of Dipstick | ||

| Fuel System | 1. Upgrade to Fuel Fitler that Integrated with Fuel Transfer Pump | Starting System | 1. 12V Starter Motor for 12V Electric System |

| Engine Shut-Down System | 1. 12V Solenoid for 12V Electric System | Power Output System | 1. Size of Flywheel Housing and Flywheel. |

| 2. Explosion-Proof Solenoid | 2. Dual-Ear Flywheel Housing (For Twin-Starter System) | ||

| ------END------ | |||

How to Order Engine to Replace Your Old Engine?

Type A: Engine Replacement Requirement (Original Engine is SDEC Engine).

This is most simple demand case, you just need to provide us the original engine name plate, and then we can easily check and confirm what exactly you need, and we also ensuring that the engine from us will be 100% same with your original engine. (In some case that the vehicle manufacturing modify the engine on their own, we are not able to supply the parts or the condition that modified by the vehicle manufacturer)

Type B: Engine Replacement Requirement (Original Engine is Cummins Engine but produced in UK, USA or other Cummins engine plant).

EMAC have rich experiences in replace the UK, USA or other engine plant produced engine, with SDEC produced Cummins engines, we required the original engine name plate photo to obtain the related information (at least we will need engine serial number, with engine model name only is useless for us, we are not able to provide quotation with engine model name only for the replacement project), and then we can check out the BOM list and all accessories of your original engine serial number, and then we can check and compare with the BOM list of our SDEC produced engine, choose the most closest SO number engine, and modify the parts that not same with your original engine, we have delivered hundreds of cases of replace the customer's original engine that produced in Cummins UK, USA or other engine plants with SDEC produced engines, you can refer to our video introduction on Youtube: https://youtu.be/dYVgRM5NsUo

We can NOT guarantee the engine produced by SDEC s exactly same with your original engine, but we can guarantee that all of engines from EMAC will have no problem with installtion and performance, which all of engines can works very well after replacement.

Type C: Engine Replacement Requirement (Original Engine is other brnad engines even gasoline engines).

EMAC also have rich experiences in replace the engine that not Cummins installed, these engines can be other brands such as Deutz, Caterpillar, Perkins, Komatsu or others, we even had experiences of replace gasoline engine with SDEC produced diesel engines.

This kind of appliaction is more complex and quite risky, EMAC can't do much thing due to lacking of information, the only thing we can guarantee is the performance after replacement, we check and compare the engine performance curve of original engine and our SDEC engine, and then we select the most suitable model for replacement. Due to we are lacking of the installation spaces and related accessories, we will send the both CAD and 3D drawing for our recommend engine model, and then customer have to evaluate the risky of replace the original engine with our engine, especially the risky of space, the possibile interactive when installation, and the risky of modify related coolant pipe, air pipes and wiring harness. Normally this kind of request consuming lots of energy and resource for us to carry on, also quite risky for us, so we will not work on the replacement quantity that below 50 units.

When your requirement is replacement, please tell our customer service team of what type of replacement you need, and provide us original engine name plate, the engine name plate is the necessary material before we start our business negotiations, we will NOT reply to all inquiry that even can't provide engine name plate.

How to Choose the Right SDEC Generator Engine for You?

To choose a suitable engine for truck, bus or special vehicle manufacturer is quite simple, because the buyer is the manufacturer, so usually they are quite flexible with space, pipes and wiring connections.

The following process are the standard process for us to select a suitable engine model for truck, bus or special vehicle manufacturer demand.

Step 1: We need basic information of the required engine, including rated power, rated speed and emission standard of the required engine.

Step 2: EMAC will evaluate the requirement and select the suitable engine model for customer, with engine data sheet, engine performance curve, CAD darwing, 3D model and budgetary quotation provided back to customer.

Step 3: Customer should check and compare the engine data sheet, performance curve and related drawing and confirm all details one by one. Most important thing is confirm the performance curve suitable for the requirement.

Step 4: After engine confirmed, we have to check and confirm the specifications of accessories one by one carefully, like the electric system specifications (12V or 24V), the detailed specifications of starter motor, charging alternator, air compressor, power steering pump, A/C compressor etc.

Step 5: Confirming the accessories positions and connections, customer need to check and confirm all positions are suitable for the project, such as engine fan, turbocharger, oil pan position, and connections of air pipe, coolant pipe, wiring harness etc.

Step 6: After confirming the engine performance, position, connection and specifications of all accessories, we will be able to provide accurate quotation for prototype and batch order. Prototype is strongly recommend to start the cooperation, to avoid the possible problem, risky on the engine with batch order.

Notes:

1: Technical support including technical training, onsite installation and commissioning services are avaiable with additional chargers.

2: We are able to supply complete powertrain system, including engine, transmission, transfer, axle, suspension etc, engine with transmission is highly recommended, because if we supply both engine and transmission, we can run simulations for the vehicle, which we usually will provide customer a simulation report, with the simulated result of Balanced Maximum Vehilce Speed and Maximum Grade Ability at different speed.

3: EMAC able supply complete chassis that integrate all powertrain system together, which can greatly reduce the manufacturer's design works and reduce the system mismatching risky.

Tips of SDEC Generator Engines!

SDEC is one of 50:50 joint venture of Cummins in China, its official Cummins factory that following high Cummins USA production and quality control standard, the SDEC factory swap every 5 years between appointed employee from Dongfeng Motor and Cummins. For more details, you can refer to the company introduction of SDEC Engine Company.

Started the production of Cummins engines in China in 1980s, Cummins products has been in China for over 40 years, thousands of people have worked for Cummins China and some of them are very skilled experienced engineer, some of them resigned from Cummins to set up their own small workshops or assembly factories that focusing on producing copy Cummins engines.

Price is always not the problem for Chinese suppliers, there are many tickies to lower down the engine prices, such as supply self-rebuild engine as new engine, supply official RECON engine from Cummins as brand new engine, assembly the fake engine with after-market parts, supply lower power model engine and change the name plate etc. You can find plenty of suppliers on alibaxx.com with various prices, the classic Chinese business style is tell you that he give you very low price and not make profit, how can you believe a businessman will make business that have no profit? They gave you low price not becuase they share their profit to you?

As a matter of fact, Chinese supplier often make their profit much more higher by selling the low quality copy products as genuine brand new products! Always remember YOU GET WHAT YOU PAID!

The key point of dealing with Chinese supplier, is to find and choose reliable business partner that will not cheat you for short-term business, but with vision of build long-term career and life-time partnership, EMAC is one of the reliable partner that not chasing for short-term high profit, but we cares our decades of good reputation and we working with all business partners not as supplier and customers, but as close friend and brothers.

FAQ of SDEC Generator Engines?

SDEC is the short name of SDEC Engine Company, take the first letter of each word, it comes with SDEC as short name, for more details about SDEC, you can refer to the company introduction of SDEC Engine Company.

2: Does your engines copy products?

This question is quite often from customer that not familiar with Cummins, Cummins have over 20 joint ventures in China now, and 6 of them are engine joint venture, which Cummins owns 50% share of all of those 6 engine plants, so all of the Cummins factories in China are genuine Cummins factory, that following high Cummins USA production and quality control standard. EMAC is the business partner of SDEC, and we are supplying powertrain and engine power pack based on genuine brand new engines from SDEC for all different applications, EMAC is a reliable and professional power system solution provider that offering abundant various options.

3: Why there are so many companies selling Cummins engines?

There are plenty of companies selling Cummins engines in China, especially on the B2B platform, such as alibaxx.com, you can find plenty suppliers there with attractive prices, Cummins products has been in China for over 40 years, thousands of people have worked for Cummins China and some of them are very skilled experienced engineer, some of them resigned from Cummins to set up their own small workshops or assembly factories that focusing on producing copy Cummins engines. You should be careful of being cheated by the attractive prices with copy or rebuild products.

4: How can I identify if the engine genuine or not?

Cummins keep working on the updating its identification system, technically, there are serial number on all key components of SDEC engines, including cylinder block, cylinder head, turbochager, fuel pump, starter motor, alternator, you can collecting the serial number (NOT part number), and then call SDEC call service center to identify if all the numbers are matching to the original number or not. EMAC continuously updating the latest Cummins identification system, you are welcome to following our website or keep in touch with our customer services team to get latest information from Cummins.

5: What's the warranty policy for the engines supplied by EMAC?

EMAC following standard SDEC warranty policy, which will update sometimes, you can following us to get the latest warranty policy from SDEC. Generally EMAC only afford the defective parts cots and shipping costs for the warranty claims, labor costs and transportation costs are not covered in the warranty.

However, EMAC is building our own independant after-sales service system now, which aims to build a global service network, with resouces of global repair and engineering network, which we believe can bring all business partner benifit in future, helping all of OEM manufacturers expanding their market into global market without worries of lacking after-sales service network. For more details about our Global Service, you can visiting www.global-service.com.

6: How about the future parts supply for the engines? Are you able to supply parts?

As the support team of EMAC's business scope, PartMac is our own brand that focusing on genuine parts directly from all brand factories.

All of EMAC’s partners are facing big challenges with sourcing original spare parts in China. Committed to providing truthworthy and professional after-sales support and parts supply, PartMac is a sub-brand of EMAC group that focusing on parts business. Stick to original parts only, PartMac can’t give any solution on CHEAP PARTS, but you don’t need to worry about any quality issues with every single parts from PartMac.

Truck Sale Manual

Installation Drawing

Installation Manual

Operation Manual

Parts Catalogue